Value Chain Management

Sustainable Supply Chain

With the UN's advocacy and worldwide trend in supply chain management, suppliers are expected to meet environmental, social, and governance standards in addition to quality, delivery, and cost to create sustainable value with partners across the value chain.

The Supplier ESG Program is overseen by the Board. Authorized by the Board, the Strategy and Sustainability Committee, led by a director, enforces decisions as the highest decision-making body, submitting outcomes to the Board annually for review. Each year, we conduct supplier sustainability risk assessments to evaluate their environmental impacts, social responsibilities, and governance practices and plan sustainable corrective measures to ensure that suppliers continue to comply with our Supplier Code of Conduct, and implement sustainable supply chain management.

In addition to the supplier assessment process, in 2023 we trained 100% of our internal procurement staff and other employees in sustainability knowledge and awareness, with a total of 448 employees participating 290 hours in the training sessions, to ensure that they understand the Company's supplier ESG program and instill ESG principles and knowledge into each employee's role and implement their daily operations. The Company promote sustainability improvements throughout the supply chain to reduce overall supply chain risk and simultaneously build resilience and capacity to respond to global climate change.

Developing Sustainability Competency in 2023:

To properly assess the sustainability risk of suppliers and ensure they comply with USI's Supplier Code of Conduct, USI suppliers are required to sign a commitment to follow the Code and respond to USI's sustainability risk assessment questionnaire based on the RBA Code of Conduct framework, which covers five aspects: labor rights, health and safety, environmental protection, sustainability and risk management, and supply chain management. These supplier risk assessments ensure their risks can be effectively reduced and controlled. On-site audits are conducted for suppliers that may have higher risks to gain a deeper understanding of their sustainability development status, implement effective supplier management, reduce risks, improve the overall efficiency of the supply chain, and strengthen the sustainable development of the supply chain.

Sustainability Risk Assessment Process:

Before conducting risk assessment of suppliers, USI must first proactively conduct supplier screening. The company selects suppliers to be included in control by annual procurement amount and identifies suppliers with potentially high risks in terms of governance, environment and social as the basis for key management.

Supplier Screening:

| Methodology for Suppliers Screening | |||

|

We proactively review and investigate all suppliers' countries/regions, their production processes, and their respective product categories to conduct preliminary assessments of suppliers and analyze potential risks.

|

|||

|---|---|---|---|

| Aspects of Suppliers Screening | |||

| Environmental | Social | Governance | Business ㄐrelevance |

|

|

|

|

To enhance overall supply chain competitiveness and ensure suppliers fulfill their corporate social responsibilities, we conduct written evaluations and on-site audits/inspections of suppliers through the SSAQ. A survey of 456 Tier-1 Suppliers was conducted in 2023, with a recovery rate of 76%. The evaluation results over the years are shown in the table below. We analyzed suppliers' SSAQ responses, reviewed and assessed high-risk suppliers, and initiated audits. In 2023, we conducted on-site/document audits for 65 raw material suppliers. For deficiencies found during the audits, suppliers are required to submit improvement plans and must implement them within a specific timeframe and undergo re-audit. Closure rates for re-audits were 100%, and the audit results were classified as low-risk.

Supplier Sustainability Risk Assessment:

| Year | Unit | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|

| Number of suppliers evaluated with sustainability metrics | - | 576 | 419 | 525 | 456 |

|

Percentage of suppliers that completed Supplier Sustainability Assessment Questionnaire

|

% | 70 | 73 | 73 | 76 |

| Number of suppliers on-site audited with sustainability metrics | - | 40 | 47 | 46 | 65 |

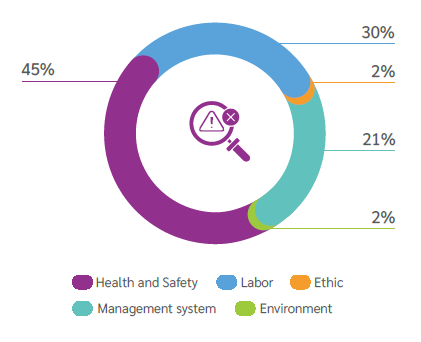

We analyzed the deficiency items in supplier audits and found that of the five major areas, 45% were health and safety. The detailed results are shown in the chart below. USI will continue to focus on health and safety improvements through counseling and advisory measures and will continue to assist suppliers with the RBA Code of Conduct and contribute to the improvement and enhancement of the supply chain business environment together with suppliers

Distribution of Supplier Sustainability Audit Findings:

USI conducts supplier human rights risk assessments to understand the importance of human rights issues in the supply chain. The results of suppliers found that "Freely Chosen Employment, Non-Discrimination/Non-Harassment, Industrial Hygiene, and Health and Safety Communication as the main human rights risk issues. We also identified high-risk suppliers and took corresponding measures to continuously track the effectiveness of their corrective actions.

Supplier Human Rights Incident Mitigation and Remediation Measures:

- Mitigation Measure

- Annual audits or RBA VAP to assess suppliers’human rights risks through each Facilities to mitigate risks.

- Requiring suppliers to adopt corrective measures for human rights risks and conduct follow-up on implementation.

- Instilling the importance of human rights in supplier labor through education and training on sustainable supply chains to reduce risks in advance.

- Remediation Measure

- Requiring suppliers to provide guidance or compensation, or to implement policy changes or other measures for employees whose human rights have been violated.

- If a high-risk vendor is identified, the Company shall conduct on-site audits and provide recommendations for improvement and require the vendor to submit improvement reports on a regular basis to track the performance of continuous improvement.

USI considers suppliers as key partners and attaches great importance to communication and interaction with them. Through supplier education and training, presentations, and technical/competency counseling, USI empowers suppliers to develop an awareness of sustainability management to meet the ever-changing trends and enhance the overall sustainability of the supply chain.

- Sustainable Supply Chain Training

- New Technology/Product Presentation for Suppliers

- Supporting Suppliers with Improvement Actions

- Supplier Carbon Mentoring Program

- Supplier Product Technology Improvement Project